Concrete crack repair

Why do concretes crack?

Many factors can lead concrete to crack:

- shrinkage of the concrete after drying: excess water in the mix or a premature drying

- oxidation of the reinforcement steel

- lack of expansion joints

- movement of the building

When the concrete has cracks that may affect the durability of the structure by causing more serious disorders that may affect the overall state of the building, it is necessary to treat them.

Passive concrete crack: a crack whose opening does not change

Active concrete crack (Non-dormant /dynamic/live): crack opening during the course of time or under external actions (traffic, wind, temperature, etc.)

How to repair cracked concrete? See the concrete crack solution below

How to fix cracked concrete ?

After the concrete crack diagnosis, if it is a structural crack, the concrete repair professional will recommend the best repair solution and choose the right sealing chemical for this situation.

There are various sealing chemicals in the market with different specifications:

- Epoxy resins (EP) may be a solution for dry passive concrete crack repair

- Polyurethane (PU/PUR/SPUR) may be useful for active cracks or to stop water ingress

- Acrylate / acrylic to cure concrete leaks from cracks

- Slurries, Cement and injection mortar could also be an option sometimes

As each job require a specific solution, we recommend you to contact your chemical sealing manufacturer to help you choose the right material: components, viscosity and pot life.

What you need to repair concrete cracks:

- Concrete drill bits: diameter 12mm in concrete in good condition, smaller if damaged

- Mabi high-pressure injection packers diameter 12mm

- Mabi Membrane pump with an injection tip.

- Injection materials / Sealing chemicals

- Personal Protective Equipment (PPE)

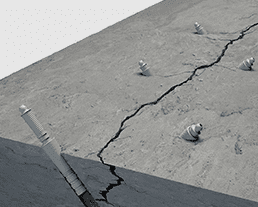

Drill

Drill Ø12mm holes, in staggered row, in each side of the concrete crack with a 45° angle to reach it in depth. Remove the dust with an air blown gun.

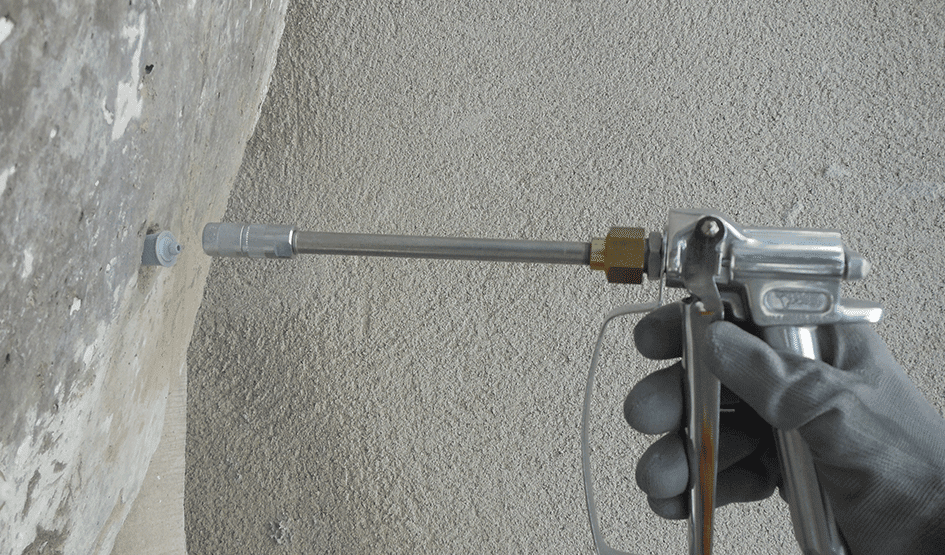

Injection-packers’ implementation

The anchoring sleeves are inserted in each drilled hole, using a hammer until a perfect fit. With a mounting tool, hammer strongly the injectionpacker into each anchoring sleeve.

The anchoring sleeve expands and firmly holds all together.

For vertical cracks, seal the crack in surface with a waterproof material to avoid the resin to come out.

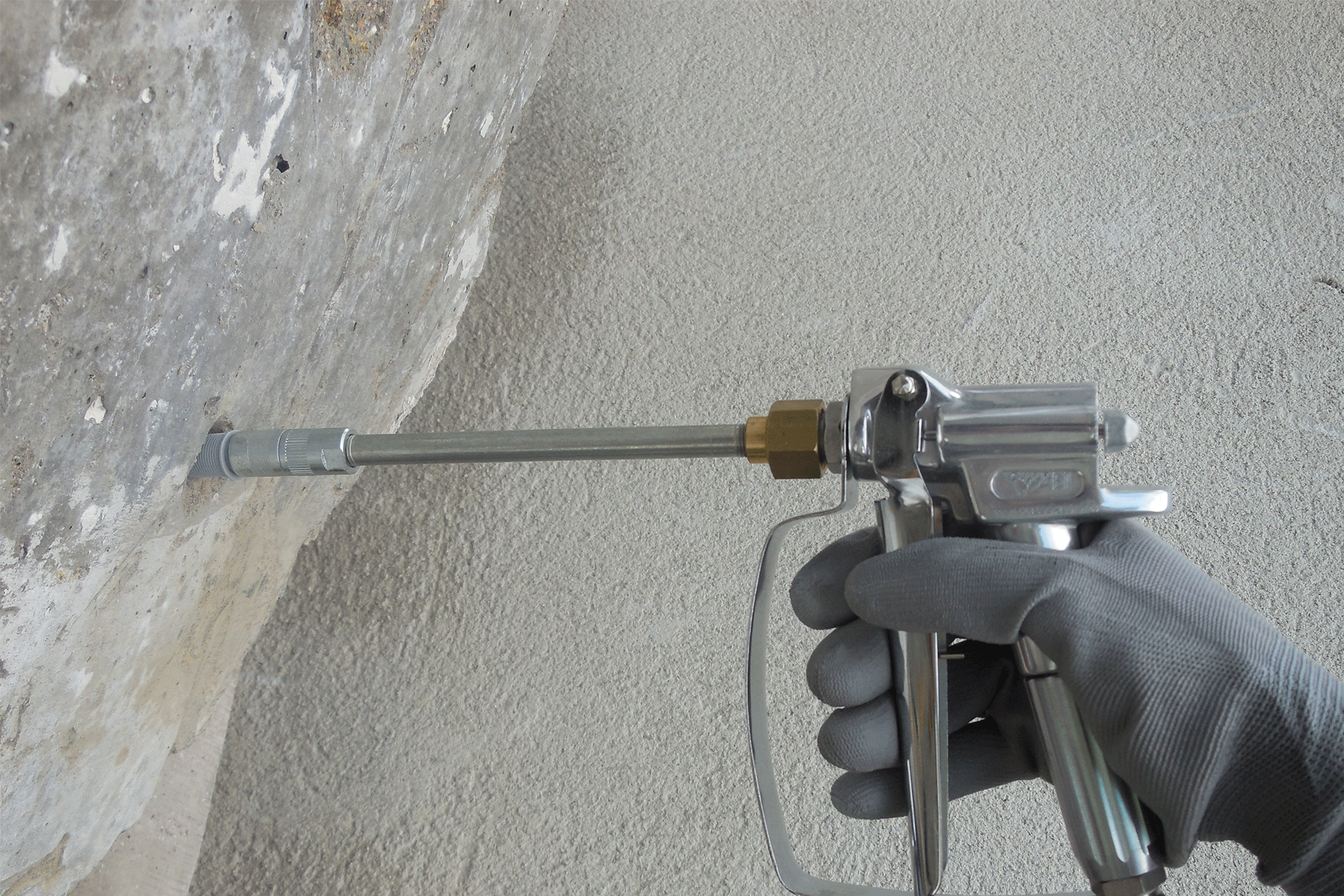

Inject

Inject gradually the injection resin depending on the concrete condition. Only use officially approved chemicals and equipment; wear the Personal Protective Equipment required.

After injection, the injection-packer head can be immediately cut and holes must be resealed.

Part of this methodology could also be applied to a large scope of application:

Dams and Tunnels

Manholes

Pipeline/Storm culverts

Sealing static/dynamic cracks

Below grade structures

Rock fissures

Expansion joint repairs

Polyjacking (slabjacking)

The methods are given for information purposes only.

Always refer to the local legislation and to the chemical manufacturer’s label before starting any job.

Always wear the Personal Protective Equipment (PPE) required and officially approved for chemical handling, including gloves, coverall, respirator and protective eyewear.