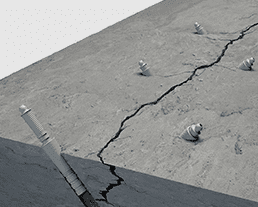

1. Identify the type of crack

When you notice the appearance of cracks in concrete structures it is necessary to act.

If cracks can damage the durability of the structure by causing more serious disturbances that could affect the overall strength of the structure, it is necessary to treat them.

There are 2 types of cracks:

- passive cracks or so-called dead cracks. These are cracks that are not progressing anymore.

- active cracks, the opening of the crack evolves with time, or through an external source (wind, temperature, traffic …)

2. How to treat cracked concrete?

- Drilling with a 12 mm drill bit: the holes must be drilled staggered on each side of the crack. with an angle of 45° to reach the crack in depth.

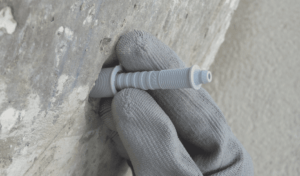

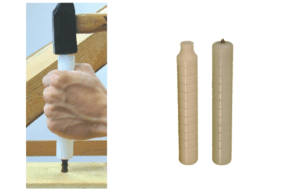

- Implementation of the anchoring sleeve with a mallet: you can also use a hammer, it is necessary to make sure that the anchoring sleeve is maintained

- Insertion of the injector part into the anchoring sleeve, place the injector with a mounting tool to protect the connection of the injector head. Hit strongly until complete stop of the injector.

- Injection of the resin, we advise you to inject the resin gradually depending on the hardness of the concrete.

- Cutting the injector’s head, once the injection is complete you can cut the heads of the injector and reseal the holes.

3. Find here the pictures of the several steps to repair cracked concrete on a jobsite

4. How to choose the right material for the repair of cracked concrete?

Mabi vous propose un kit “réparation des fissures dans les bétons” complet avec :

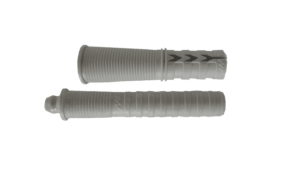

100 HIGH-PRESSURE INJECTION-PACKERS

In two parts: an anchoring sleeve + an injector Ø12x60mm, grey, with a moulded round head nipple and a 3mm steel ball. Injection pressure from 1 to 150 bars. Please note that the maximum pressure may vary depending on the type of structure and its condition.

The check valve is located in the middle of the injector to stop the resin’s backflow even after the injector’s head cutting.

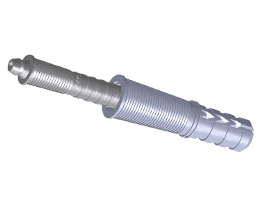

1 MOUNTING TOOL

For the insertion of the injector part into the anchoring sleeve without damaging the head of the injector.

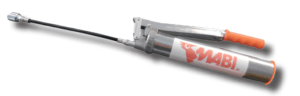

1 MANUAL HIGH-PRESSURE PUMP FOR RESINS

With a 30cm hose and a coupling for Moulded Round head nipple. 550ccm capacity. Weight 0,96kg. Light, economical. Ideal for injection of small quantities of epoxy or polyurethane resins with high-pressure.

Where to get equipment that meets the requirements and standards?

For a personalized quote according to your needs and quantities.