Which injector / injection-packer I need?

MABI invented the plastic Mechanical Packer in 1969 and then has developed a wide range of injection ports. The aim of this article is to help you choose the Packer suitable for your chemical injection project.

An injection packer is the connecting piece between your injection pump and the structural element for the injection of various sealing chemicals, including Epoxy resins (EP), Polyurethane (PU/PUR/SPUR), Polyurea, Acrylate Gel, Hydro Active Foam Grouts, Siloxane, Silification products, Micro emulsion, Slurries, Cement and injection mortar…

In the market, there are steel packers and aluminium packers but we decided to produce only plastic injection ports because they cover a large range of applications and can handle low and high pressures. Also, Plastic packers are inexpensive, set very quickly increasing productivity on the job site and are easily disposable after use (called « One day packer »). Last but not least, their lightweight enable you to save money on shipping.

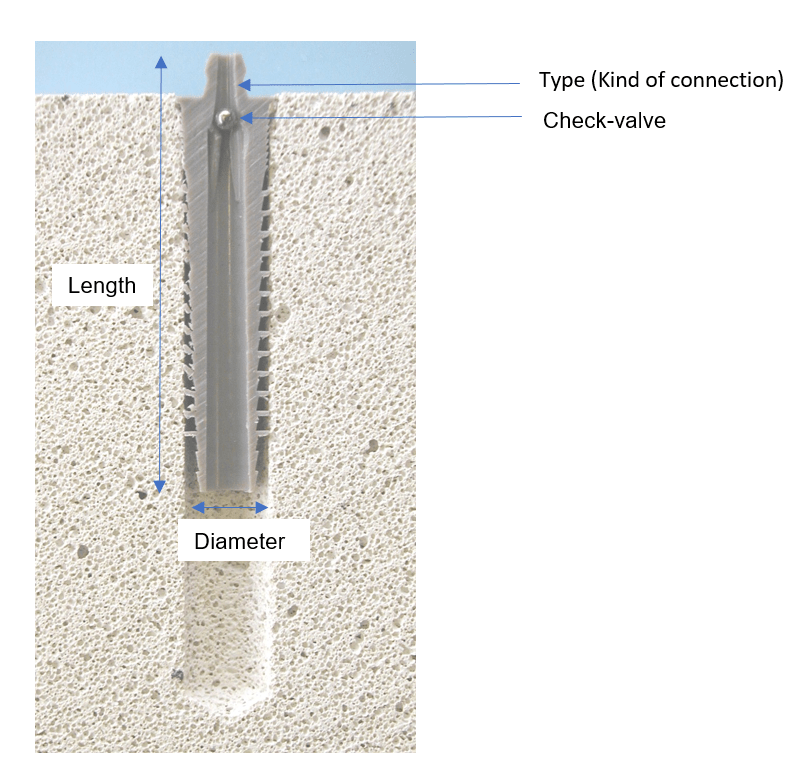

Each mechanical injection packer has different characteristics

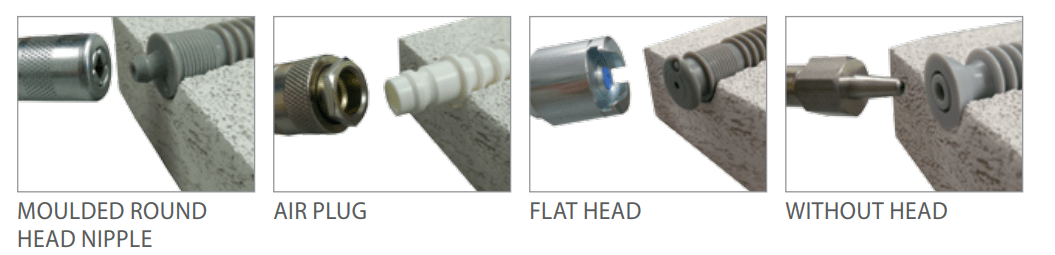

What are the different types of injection packers (kind of connection)?

To fasten your hose or gun on the injection packer, the top part could be:

- Zerk fitting / With head / Nipple grease nipple / Moulded round head nipple

- Button Head / Flat head

- Pneumatic head / Air plug

- Without head

MABI’s injection packers have the top part molded on the packer. No need to struggle screwing the zerk fitting on the port.

The most popular connection is the Zerk type for the widepread availability of the injection equipment with 4 jaw couplers and its quick set up/disconnect.

The Button-top allows a more secure connection to the port, minimizing the leak issue and allowing the technician to be on the side during the injection in case of blow-out of the packer if they exit the drilled hole.

What diameter of packer should I use?

In most construction materials, the size of the drilled hole equals the outer diameter of the mechanical packer: use a 12mm drill bit for a 12mm packer. But if the construction material is brittle you may use a smaller drill bit.

Usually, a larger packer has a better grip and permits higher injection pressures but larger boreholes can damage the structure.

The choice of the inner diameter of the packer depends on the volume to be pumped and the thickness of the chemical resin injected.

MABI range of packers goes from 6.5 mm to 18 mm.

Are there different lengths of injection port available?

Sizes of our injection ports vary from 15 mm to 80 mm.

In a few applications, such as the curtain injection, where the chemical injected inside a building should reach the other side of the structure, extension rods can be adapted at the bottom of the injection-packers. There rods can be cutted to the length of your need.

What is the purpose of a check-valve and its location inside the injection packer?

A few injection ports haven’t got any check-valve, for a free passage of slurry, cement or injection mortar. To prevent back-flow, a cap can be adapted to the packer’s top.

Most of our plastic injection packers have a 3mm metallic ball valve to prevent back splashes of chemical and force the injection material to remain and diffuse inside the structure.

A 6mm plastic ball valve is available with our reference 01040018. This large inner passage is useful for the injection of thicker products.

When a 2-stage injection is needed in a structure with cavities, hollows and voids, a mix of two systems is possible:

– Cement injection through a Ø12mm injection-packer without valve to consolidate the structure

– Insertion of a Ø6.5mm injection-packer inside the Ø12mm one, to provide a non-return system and to inject your chemical resin under pressure.

In the low-pressure injection-packers, the check-valve is situated on the top part because, after the injection, the packer is pushed inside the bore hole and remain in the structure hided with a suitable sealant.

However, in the high-pressure injection packer reference 01090050, the check-valve is situated in the middle. Indeed, the high pressure port can not be pushed further into the bore hole after the injection and the top part has to be cut. The check-valve’s location in the middle allows to keep the anti-return valve in the structure after cutting the packer so the injection material never leaks back.

Please watch the video about how to use an injection packer:

Over the years, MABI has been a pioneer in supporting contractors and aplicators in leak / seal repair and waterproofing, bringing innovations to work efficiently, quickly and safely.

Our R&D department is on your side to develop new products according to new industry challenges.